Since April 2014 the DVSA have been recommending commercial vehicles undertake 4 brake tests per year!

This is a recommendation based on the DVSA’s guidance paper.

So as this is a recommendation, what is the law? Is the law is one RBT as a MOT per year?

Well it is if the DVSA is a guidance paper, or is it?

If the guidance set out by the DVSA isn’t followed and the operator is inspected by the DVSA or addressed by a traffic commissioner. The guidance set out by the DVSA is used as the standard an operator should meet, does this now make it law?

Well the operator has to make this call; do you follow the guidance or not? Keeping a fleet roadworthy and safe must be a high priority for any management team, after all the with laws around corporate manslaughter all risks need to be seriously considered.

Many operators have moved with the guidance but still 5 years has passed with some commercial vehicle operators still unaware of the law and guidance.

So, regarding commercial vehicle brake testing, the guidance states:

Document :Guide to maintaining road worthiness

Commercial goods and passenger carrying vehicles (Revised 2014)

Section 5: Safety inspection and repair facilities

Extract –

“Therefore, it is normally expected that the vehicle or trailer should complete at least three successful brake efficiency tests spread throughout year in addition to the annual MOT test.”

An operator can take the decision to carry out brake tests using roller brake tests or a decelerometer.

As the consequences of non-compliance with the required standards can be very severe and include prohibition, fines or prosecution, operators are advised to ensure that they are familiar with all the changes within the DVSA guidance.

Following The Bath Tipper Incident Inquiry, HGV Brake Testing is Essential!!

The inquiry showed the Bath tipper truck to have been poorly maintained which resulted when tested to have a very poor brake efficiency.

aide automotive recommend the use of roller brake testers and decelerometers within a 12-month maintenance and testing policy.

Also, the use of an Infra-Red Temperature Gun, Infra-Red Temperature guns are an excellent way of individual brake testing of wheel disks or drums to determine brake activation. With the ease of just pointing the Infra-Red Light at the wheel hub from the outer edge of a trailer or truck and without removing wheels, an infra-Red Temp Gun can indicate if a wheel is not braking efficiently as compared to the other wheels on the vehicle.

aide automotive market a range of Brake Testing, Servicing & Diagnostic Tools for commercial vehicle workshops.

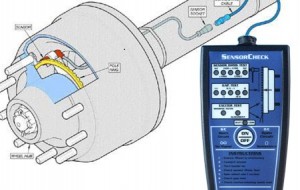

With the Bowmonk BrakeCheck Portable Decelerometer Printer kit, a workshop can meet the 3 additional required brake tests with minimum fuss. For Trailer Servicing & Diagnostics, aide offer a complete Trailer Electrical (ABS Light & EBS CAN Line Test), Light and Air Brake Tester with Diagnostics interface for Trailer ECU Code Reading / Clearing and management data viewing. EBS/ABS Sensor Master testing can be conducted with the Sensor Master, while Battery Diagnostics Tests with a Midtronics MDX Battery Tester.

aide automotive offer a range of products to help with DVSA Guide To Roadworthiness. Contact us via our website www.aideautomotive.com

HGV DVSA Truck Brake Tester

aide auto Market Truck & Trailer Workshop Test Tools