aide automotive have posted the user guide for the BrakeCheck TT (Truck & Trailer).

Commercial Vehicle Brake Testing

The following criteria are required for all HGV & Trailer brake testing.

All brake testing should be carried out away from the sites working area; this should be done in an area that has roughly level ground.

The MOT performance figures are for the Peak Reading:

Tractor Unit Service Brake Bare Minimum 50 %

Tractor Unit Secondary Brake Bare Minimum 25 %

Tractor Unit Parking Brake Bare Minimum 16 %

Although the test requirement looks for a peak reading, you could use the relationship between the peak and average to determine brake performance, if you achieved a peak reading of say 51 – 58 this is not indicating good brakes, peak figures of 70 + can be achieved to indicate good brakes, even though high peaks are recorded if a low average is recorded (20 – 30 example only) this would indicate bad brakes or you will more than likely fail a roller brake test!

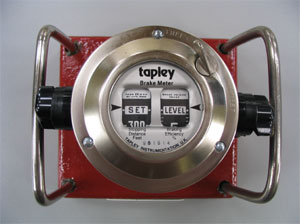

Brake Tester Position

The brake tester should be positioned in the foot well of the vehicle, preferably up against a bulkhead with the direction of travel arrow pointing in the intended direction and with the tester straight.

Vehicle Test Procedure

With the vehicle stationary, position and arm the brake tester, accelerate the vehicle at a constant rate in a straight line up to a safe site speed then apply the brakes in an emergency stop manner, hold the vehicle on the brake until the vehicle has come to a complete rest.

Arming The Brake Tester For A Tractor Unit Test

BrakeCheck TT (4 Truck & Trailer) has a 99 test memory on the Service, Hand & Trailer feature.

Turn the BrakeCheck on by pressing and holding MENU until Sbr is displayed on the screen.

Press ENTER, the display will now show C1 (Wet Ground), this can be used to indicate test ground condition, Press MENU to alter to C2 (Dry Ground) or C3 (Snow/Ice Ground) & C4 (Tarmac Ground). Press ENTER and the level indicator L-| |- will now show, if this is not the case re-position the BrakeCheck until achieved.

Press ENTER the display should now read 0.00 ± 5. As described above accelerate and brake.

At the end of the test the display will show L#, this is the test number, press ENTER to store the test, (remember to write down your vehicle ID and test number) if the display still shows L-| |- you did not press ENTER!! The peak reading will report after you pressed ENTER,

With the Peak reading displayed press ENTER, this will show the average reading. Pressing ENTER again shows further information.

For a Hand Brake Test press MENU twice, this is while the service brake results are displayed, the display should now show Hbr, now go to the second paragraph under Arming The Brake Tester to carry out a Hand Brake Test.

Commercial Trailer Brake Testing

VOSA offered guidance on testing commercial trailers and advised, “The way to use a decelerometer is to first test the drawing vehicle on its own. Then connect the trailer and the deceleration rate should be similar i.e. the trailer is doing its fair share of work. This is not an exact science but would be enough to give you confidence the trailer brakes were working.”

Further individual brake performance testing can be done by using an Infra Red Thermometer to measure brake disc or drum temperatures, this can be done after brake testing or when vehicles are returning from a journey. An optional accessory to the BrakeCheck TT kit is an Infra Red thermometer; please consider this as a very useful way to review individual brake performance!

We suggest you test a tractor unit on the day you are required to test trailers, to test trailers first test a tractor unit, this only needs to be carried out once, you can then add multiple trailers to the tractor unit through the day, no need to test a tractor unit every time you test a trailer. Trailer tests will be associated with the last tractor unit Service Test!

We recommend clearing the memory of the BrakeCheck TT prior to testing trailers, Turn on the BrakeCheck by Pressing and holding MENU for 3-4 seconds, the display will show Sbr, press MENU until Clr is shown in the display, this will happen after Temperature. Press ENTER, wait for 3 straight digits to move across the display and reset to Sbr. This has now cleared all memory.

Test a tractor unit or shunter, you may warm the brakes up prior to testing if the vehicle has been sat for a period. Test a tractor unit or shunter as per previous guidance Arming The Brake Tester For A Tractor Unit Test. Once an acceptable test has been recorded leave the test in the memory, remember the trailer brake test will be associated wit the latest Sbr brake test in the memory! If one test was completed this will be test 1.

Trailer Brake Testing

Press MENU to turn the BrakeCheck on, with Sbr on the display press MENU twice, trb will be displayed. With the BrakeCheck positioned in the pulling vehicle, press ENTER, the display will now show C1 (Wet Ground), this can be used to indicate test ground condition, press MENU to alter to C2 (Dry Ground) or C3 (Snow/Ice Ground) & C4 (Tarmac Ground). Press ENTER and the level indicator L-| |- will now show, if this is not the case re-position the BrakeCheck until achieved.

Press ENTER the display should now read 0.00 ± 5. Accelerate and brake the combination, when testing trailers we recommend a gradual acceleration and then a controlled emergency stop. Once the test has been completed the display will show L#, this is the test number, press ENTER to store the test, (remember to write down your vehicle ID and test number) if the display still shows L-| |- you did not press ENTER!! The peak reading will report after you pressed ENTER, as per the VOSA guidance stated above this should be similar of the service brake test of the pulling vehicle to confirm a trailer pass.

To Print:-

Point the front of the BrakeCheck at the Printer about 10-30 cm’s apart.

To Print a Service Brake:

If the BrakeCheck has powered-down due to inactivity:

Press until the display shows Sbr.

Press three times until the BrakeCheck display shows Sbr and the bottom half of the BrakeCheck shows two lights, one on Service Brake Test and the other on Last Test Result

Press once, the display will show L n, press MENU the display will show L A (pressing ENTER now will print off all tests in the memory), Press MENU and the display will show L 1, pressing MENU will increase the test number by ONE, holding down MENU will increase the test number at a rapid rate.

With the desired test number on the display press ENTER, the Peak Reading will be displayed, with the printer switched on and the BrakeCheck pointed at the printer press PRINT. Each print out will take roughly 10 seconds to print.

This is not necessary if the unit has not powered-down, the Peak Deceleration (Front/Rear) LED will be lit and the display will show a value, eg:

Make sure the printer is turned on by pressing the button on the front of the printer; a green light should now be on.

If a green light is flashing the printer needs recharging!!

If you have an orange flash your paper is getting low!!

Press once, the display will show:

and the printer will print the results for the last test performed.

Now do the same for the Hand Brake and Trailer Brake but have the Hand or Trailer brake test light and LAST TEST RESULT illuminated on the BrakeCheck.